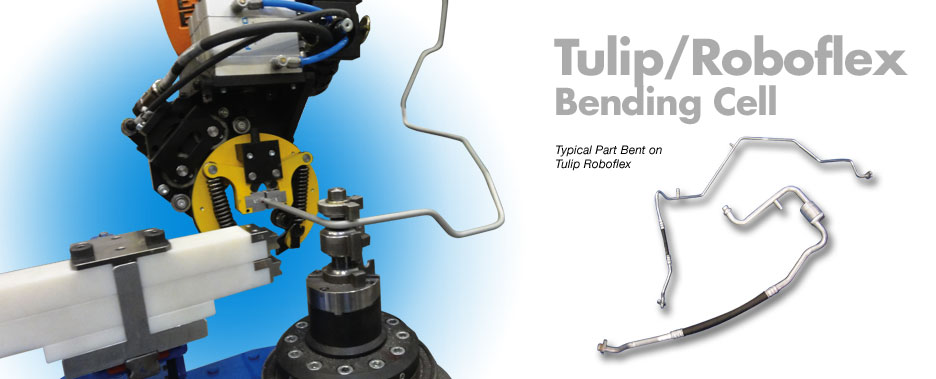

Tulip Roboflex

Tulip Bending Cell

Integrating Robotics with advanced tube bending technology, Eaton Leonard has developed a new, proven concept to bend tubes: this is the Tulip.

The Tulip bending head allows bending clockwise and counterclockwise rotation, on the same part. This new bending head does not incorporate a conventional bend arm, but, instead, uses unique tooling positioning to eliminate conventional interference issues, thereby enabling bending of the most difficult, complex part shapes.

Using a KUKA robot to manipulate tubes, the Tulip is extremely flexible with exceptionally fast throughput , and does not require additional handling devices.

Unique capabilities include bending of hybrid tubes with accessories attached, automatic loading and unloading, and the ability to produce both short and long tubes.

Programming is intuitive using XYZ/ LRA format with many automated functions , and has automated correction loop with the Vector 1 tube measurment center

Many options are available ( gravity, or step by step loader, control by camera, endformer, welding sensor, etc.)

Two models are available: Tulip 18 and Tulip 42

Tulip 18 Specifications:

- Tube OD: 4 to 16mm (steel)

- Radius: 15mm to 40mm

- Tube length: 200 to 4000m

- Two levels (two radius, or two diameters, & four different clamp forms)

- Eight axis controller

- Typical cycle time by bend: 0.9s

- Typical applications: brake line, air conditioning, fuel line, etc

Tulip 42 Specifications:

- Tube OD: 16 to 42mm (steel)

- Radius: 25 mm to 90mm

- Tube length: 200 to 3000m

- Two levels (two radius, or two diameters, & four different clamp forms)

- Nine axis controller

- Typical cycle time by bend: 1.4s

- Typical applications: aircraft, automotive (anti-sway bars)